Plain or custom printed pouches with gusseted base for stand-up stability. Wide variety of materials available.

Enhanced Production Efficiency

Stand-Up Pouches are engineered to work seamlessly with high-speed AUTOBAG® FAS SPrint SidePouch Bagging Systems that bring efficiency and enhanced through to the bag filling process.

Versatile Convenience Options

Stand-up pouches are available in food grade materials, including high barrier, and are also compatible for a variety of medical applications.

AUTOBAG® Brand pre-made Stand-Up Pouches offer a dynamic solution that not only enhances operational efficiency but also caters to the convenience preferences of consumers.

These versatile packaging options come in a range of gauges and material configurations that can be food grade and include barrier properties, added stiffness, gloss or matte finish.

Our Stand-Up Pouches are engineered to complement the high production output of AUTOBAG® brand FAS SPrint systems for both food and industrial applications. This powerful combination enables businesses to achieve faster production speeds, increased versatility, and improved productivity while minimizing labor requirements.

Added features such as the ability to stand on shelf, handles, reinforced headers, recloseable zippers, or tear strips maximize merchandising and consumer convenience that creates a lasting, positive brand impression.

Stand-up pouches are available in a variety of sizes with gussets ranging from 2" to 8" in 1" increments, and materials provide excellent stiffness and gloss for maximum brand impact. Applications include food (fresh and frozen), medical and a variety of industrial products.

- Standard Materials: Laminated stand-up pouch with excellent stiffness and gloss for maximum brand impact. Featuring a proprietary LLDPE/LDPE resin blend as the sealant layer, which is laminated to 48-gauge polyester. Typical applications include food (fresh and frozen), medical and a variety of industrial products.

- Matte Finish Materials: Matte finish materials feature a proprietary sealant layer which is laminated to a matte finish, 48-gauge polyester layer, creating a unique look and chic, modern feel for product differentiation.

- Sustainable Materials: A more sustainable value option features our completely polyethylene-based laminate material, utilizing proprietary blends of polyethylene resins to improve recyclability. NOTE: Recyclable via store drop-off. Sealed Air has determined that this material is RIC#4 and suitable for recycling via store drop off locations. Check for locations near you.

- Barrier Material: Our barrier stand-up pouch material that boasts a 9-layer Nylon with EVOH sealant layer is ideal for products that require aroma, gas, flavor and solvent containment – or a lower oxygen transmission rate (OTR).

Features and Benefits

- Available with barrier properties to extend food shelf life

- Consumer convenience features such as recloseable zipper, easy-to-open perforations, tamper evidence, or handles

- Versatile material selection for food and non-food items

- RIC4 – LPDE “store drop-off” recyclable materials available

- Plain or printed, gloss or matte, up to 8-color reverse-print process to resist abrasion and chemical breakdown

- Compatible with AUTOBAG® FAS SPrint SidePouch Bagging Systems, regular or food grade

Specifications

Wide range of material types available, including:

- Standard Materials (PTCL / PTWH) – Provides excellent stiffness and gloss for maximum brand impact

- Matte Finish Materials (MPCL / MPWH) - Provides excellent stiffness for maximum brand impact and a subdued sheen for a chic, modern feel

- High Sustainability Materials (SUPE / SUPW) – Sustainable options made from polyethylene-based laminate material

- Barrier Material (PBAR) – Offers a lower oxygen transmission rate (OTR)

- RIC4 – LDPE Store Drop-Off Recyclable – all purpose, can be food grade

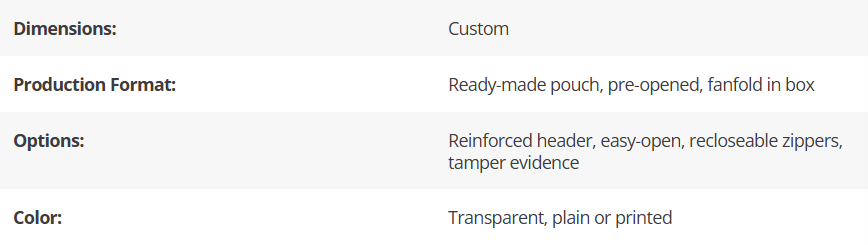

Food grade materials comply with FDA requirements for food packaging, Letter of Guarantee available on request.