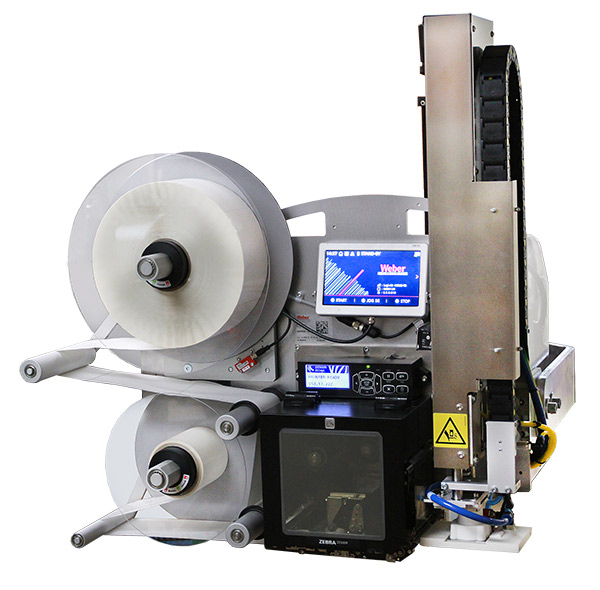

The Weber Model 4050 tamp-blow print-apply system features high-speed operation with high-resolution printing all in a modular package. The modular design offers fast in-field repairs affording limited downtime and maximum up-time.

The highly accurate tamp-blow method of label application allows you to provide a non-contact method of labeling your products quickly and efficiently on your production line.

The Model 4050 Controller

• 7” color touch display allows easy access to all parameters.

• 7” color touch display allows easy access to all parameters.

• Numerous I/O’s to allow interfacing with many types of external devices

• One-to-one media consumption. Label unwind and rewind dimensions are matched to the system’s ribbon supply to ensure they are consumed at the same rate, reducing downtime and eliminating partial changeovers

Features

4050 Tamp-Blow Label Printer Applicator

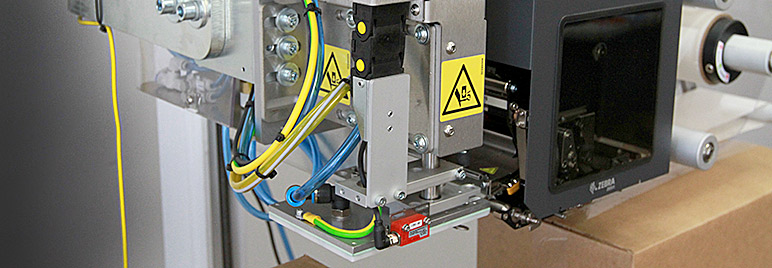

• Modulated vacuum significantly reduces compressed air consumption

• Motorized label unwinder for reduced wear on print engine and smooth feeding of the supply roll

• 7” color touch display for parameter changes, error diagnostics, productivity and maintenance status

• Zebra and Sato print engine compatible; 203, 300 and 600 dpi available

• Thermal transfer or direct thermal printing

• Heavy-duty 24/7 usage

• Capable of handling print speeds up to 18 ips

• Various tamp lengths and pad sizes available

• Available with RFID capability

• Variable stroke operation

• Label-on-pad detection

Specifications

Dimensions

30.13”L x 27.9”W x 22.98”H

(76.5cm x 70.9cm x 58.4cm) Weight

Weight

165 lbs. (75kg)

Electrical

92 to 263V AC/50-60 Hz, 5 Amp

Air Requirements

7 cfm at 72 psi

Product Sensing

Photoelectric

Communication Interface

Volt-free outputs (relays), optocoupler inputs, M12 connection for photocell and alarm lamp

Printing Methods

Direct-thermal and thermal-transfer

Print Resolution

203, 300 or 600 dpi, dependent upon print engine selected

Label Roll Size

Maximum diameter 13.75" O.D. (350mm)

Labeling Speed

Contingent upon print engine and label size/content

Label Placement

Accurate to ±0.03" (.76mm) when labels are produced to specifications and product handling is controlled and consistent

Labels

Die-cut, waste removed with 0.125" (3mm) minimum separation between labels in running direction and 0.125" (3mm) maximum web over label width; direct or thermal-transfer

Labeling Software

Weber Legitronic® software

Print Characters & Bar Codes

Text: Selection of fonts, including OCR-A & B representation

Bar Codes: UPC-A/E, EAN-8/13, Code 39, I 2 of 5, Code 128, Codabar, MSI, 2 of 5, Code 93, UPC Bookland, Matrix 2 of 5, Postnet, UCC/EAN 128, PDF-417, Maxicode, Data Matrix

(Text and bar codes can be rotated 360 degrees; horizontal and vertical character expansion)

Max Print Width

• Zebra ZE511 203, 300 and 300 dpi: 4.09" (104mm)

• Zebra ZE521 203 and 300 dpi: 6.6" (168mm)

• Sato S84-ex: 4.1" (104 mm)

• Sato 86-ex: 6.6" (167.5 mm)

Print Speed & Resolution

• Zebra ZE511 203 dpi: Up to 18.0"/second (457mm)

• Zebra ZE511 300 dpi: Up to 14.0"/second (356mm)

• Zebra ZE511 600 dpi: Up to 6.0"/second (152mm)

• Zebra ZE521 203 dpi: Up to 14.0"/second (356mm)

• Zebra ZE521 300 dpi: Up to 12.0"/second (305mm)

• SATO S84-ex Series: Up to 16", 14" or 6"/second (406.4mm, 355.6mm, 152.4mm) @ 203, 300 or 600 dpi

• SATO S86-ex Series: Up to 14" or 12"/second (355.6mm, 304.8mm) @ 203 or 300 dpi

Label Width Range

• Zebra ZE511 203, 300 and 600 dpi: 0.625" (16mm) to 4.5" (114mm)

• Zebra ZE521 203, 300 and 600 dpi: 3” (76mm) to 7.1" (180mm)

• Sato 84-ex: Max 5.16" (131mm); Min 0.51" (13mm)

• Sato 86-ex: Max 7.09" (180mm); Min 2.13" (54mm)

Optional Features

• Adjustable Stand

• RFID upgradeable print engine

• Label-on-pad sensor

• NRTL ready

• Beacon alert lights

• Available stroke lengths: 4”, 8”, 12”, 16”, 20” 24”

• Available tamp pad sizes: 4.5” x 6”; 4.5” x 8”; 6” x 4”; 6” x 6”. Pads are configurable (punchable) to specific label sizes.

- Print & Apply:

- Yes