Increased global competition is driving leaner operations in today's manufacturing facilities. To gain efficiencies, more companies are incorporating disruptive technologies, such as robotics, across their plant floors.

Combi Packaging Systems now introduces robotic technology into end-of-line packaging lines, including solutions for random case erecting.

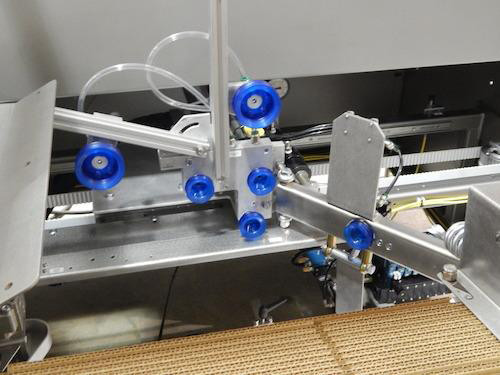

The Combi RCE Robotic Random Case Erector combines a FANUC M20iA/20 six-axis robot with multiple case magazines and a bottom flap folder with an integrated 3M™ tape head for random box erecting. The FANUC robot has a flexible end of arm tool to pick and erect multiple cases, eliminating the need for multiple erectors, the floor space they consume and costly changeover downtime.

Standard Features

Below is a list of the features that are included standard, please request a quote to learn how our engineers can design a custom robotic packaging machine to fit your specific random case erecting needs.

- FANUC M20iA/20 Six-Axis Robot

- Flexible End-of-Arm Tooling with Vacuum and Dropped Case Detection

- Dual Drive Powered Magazines

- Bottom Flap Folder with 3M™ Tapehead

- Allen-Bradley™ Operator Interface

- Fixed Robot Base, anchored to floor

- Programming for Robot, PLC/PMC, HMI and Vision

- Robot Perimeter Barrier Guarding with Safety Interlocking Doors

- On-Site Training and Support