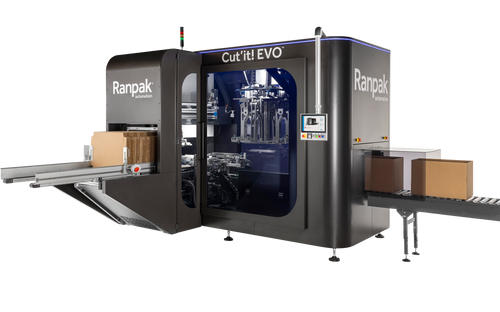

Ranpak Cut’it!™ EVO

Smaller voids and lower costs

The Cut’it!™ EVO automated in-line packing machine reduces voids in parcels before shipping, cutting down on shipping costs. It automatically shortens cartons to match their highest point of filling, and then glues a lid securely in place.

The solution of choice for distribution centers worldwide.

Cut’it!™ EVO is used across a wide range of industries including consumer goods, beauty and healthcare, office supplies, graphic arts, electrical/electronics, and tools and hardware.

Ranpak Cut’it!™ EVO Features

High throughput

Packs up to 15 boxes/minute for very high packing throughput, especially during periods of peak demand.

Flexible

Configurable box sizes in a range from 150 x 230 mm up to 450 x 650 mm.

Small footprint

Cut’it!™ EVO has a small footprint, and integrates easily into any logistic environment.

Optimized for maintenance

Large doors offer easy access for cleaning and repair, and remote diagnostics facilitate maintenance.

Ranpak Cut’it!™ EVO Specifications

TECHNICAL DATA

- Automatic height reduction to box contents

- up to 25mm with “S” frame

- up to 55mm with “M” and “L” frame

- Standard long ergonomic magazine (walk in) – can be filled in without stopping the machine

- Capacity: up to 15 boxes/minute

- Most movements servo-guided

- 4 lid flaps glued with full glue lines

- Interface: intuitive touchscreen panel

- Easy, fast and inexpensive size adjustments

- Power : 3×380 (400) VAC 60Hz

- Consumption: 10kW

- Compressed air requested pressure: 6 bars

- Consumption: 80 nl/cycle

Sizing that fits your needs.

The Cut’it!™ EVO machine is available in 3 standard frames: Small, Medium and Large. Within the limits (mini/maxi footprint) of its frame, a machine can easily be adapted to another footprint after a while.

Solutions for production storage.

Lid blanks are stored in a magazine which can be loaded without stopping production. Placed at a very ergonomic height, motorized and horizontal, this magazine has a standard length of 1750 mm, which offers high autonomy. Lids are extracted from the magazine with dedicated piloted suction cups.

Innovative touch screen display.

The operator interface is a color touch screen. Parallel to the basic operations, this display allows visualizing the machine, the state of the various stations and, if needed, guides the operator solving a problem by indicating the necessary actions to do step by step.