The Technoplat 708 CS (Clamp, cutting and sealing unit) or CW (cut and weld) semi-automatic turntable stretch wrapper cuts and attaches the film tail to the load at the end of the wrap cycle for superior load containment.

The Technoplat 708 CS/CW pallet wrapper saves 2 minutes of labor per load by keeping the operator on the fork truck. For the average customer, this translates to labor savings of $29,000 over 5 years and $60,000 over the life of the machine!

Our Remote Control start allows the fork truck operator to start the wrap cycle while staying on the fork truck. This allows them to leave the current load to pick up and stage another load which improves productivity.

R-Connect now included as standard feature (includes 36-month initial cellular data plan).

Our innovative CUBE Technology offered on this machine combines the following four (4) key factors to successfully wrap loads & ensure that they reach your customer in “as-made” condition by maintaining proper wrapping standards.

- Reduces film costs 30-55%

- Improves load containment

- Reduces product damage by 40%

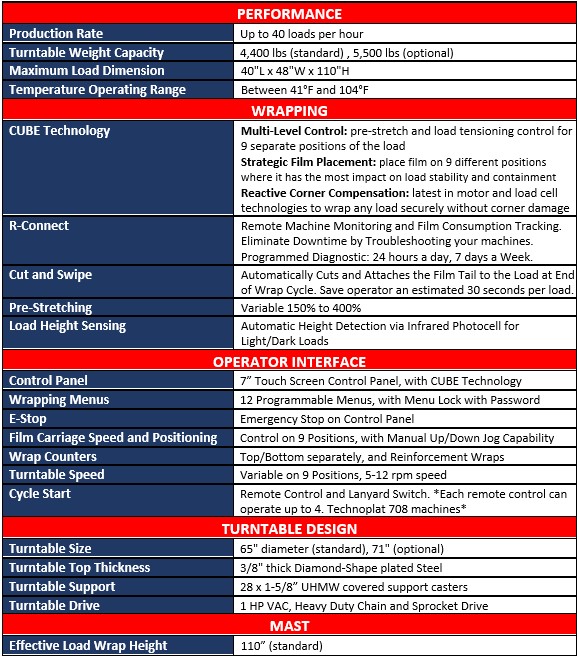

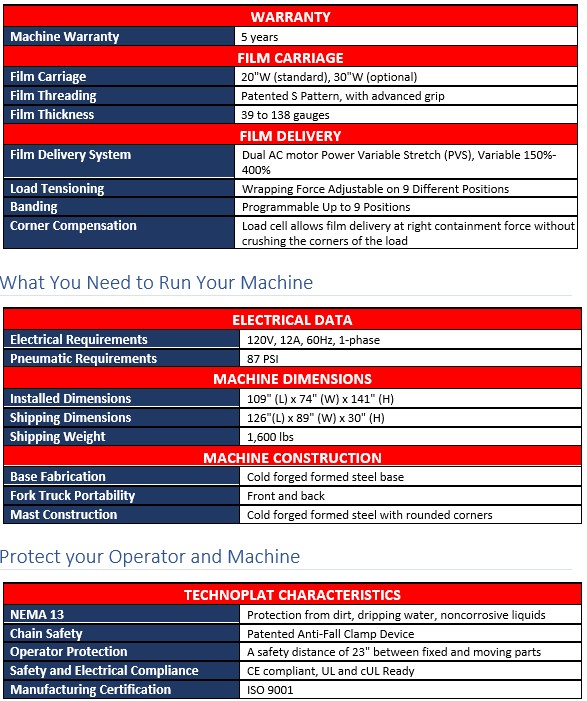

- Operation Type:

- Semi-Automatic

- Stretch Wrapper Type:

- Turntable

- Maximum Wrap Height:

- 110"

- Maximum Loads Per Hour:

- 40